The difference between steel coil and steel strip

Time:

Jun 07,2024

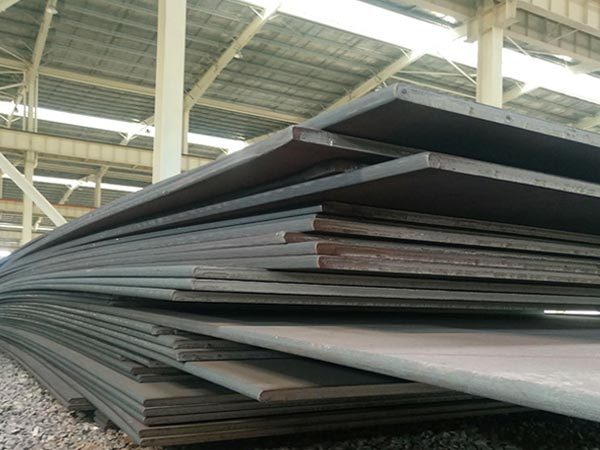

Steel coils usually refer to steel strips with a width of not less than 600 mm, which can be cut flat into steel plates or longitudinal steel strips. After unwinding, the length of steel coils can reach 1250-1500mm, and the width varies from 2.5 meters, 4 meters, 6 meters, etc. They are mainly used for rolling in large rolling mills. Due to their wide width, large equipment is required for processing. Steel coils have a wide range of uses, including construction, automobile manufacturing, machinery manufacturing, power and other fields.

Steel strip refers to a narrow coil, commonly known as narrow strip steel and medium and wide strip steel. In a narrow sense, strip steel mainly refers to a narrow coil, commonly known as narrow strip steel and medium and wide strip steel. According to the statistical classification indicators of the National Bureau of Statistics, coils below 600mm (excluding 600mm) are narrow steel strips or narrow strip steel. 600mm and above are wide steel strips. The use of steel strips is relatively specific, mainly used in the production of spiral steel pipes, etc.

In summary, the main difference between steel coils and steel strips is their width and applicable production and application scenarios. Steel coils usually refer to rolled steel with a larger width, while steel strips refer to rolled steel with a narrower width. The two have different uses and advantages in industrial applications.